CONSUL

Hebebühnen

made in Germany

Für jede Werkstatt die passende Lösung und das garantiert in bester Qualität – Made mitten in Germany!

TÜV Zertifikate

KFZ-Werkstatt

Consul-Hebebühnen gehören seit vielen Jahren zu den must-haves jeder professionellen Autowerkstatt. Bei uns finden Sie für all Ihre Ansprüche die passende Lösung, Hand drauf!

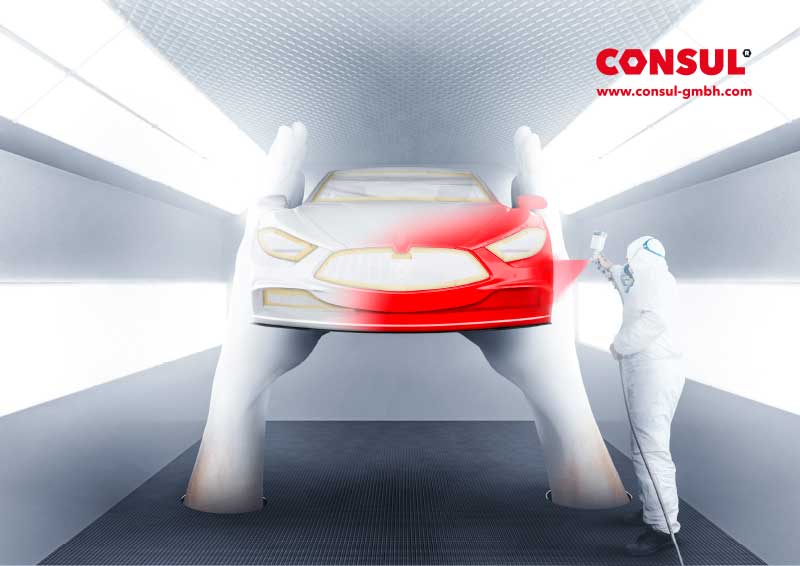

Karosserie- und Lack

Wo Sauberkeit und Präzision gefragt sind, geht Consul einen Schritt weiter und bietet Ihnen die gesamte Palette an Hebebühnen, die ein moderner K&L Betrieb benötigt, um das Fahrzeug ganzheitlich behandeln zu können.

Logistik

Für das sichere Heben von Gabelstaplern und anderen Flurförderfahrzeugen bietet Consul spezielle Hebebühnen, sowie Aufnahmezubehör, die sich von konventionellen KFZ-Hebebühnen deutlich unterscheiden.

Industrie

Das Thema Heben spielt nicht nur im KFZ-Bereich eine große Rolle. Consul bietet auch für besondere Anforderungen immer die optimale Lösung. Ob Pharmaindustrie oder Freizeitbereich bis hin zum Maschinenbau und vieles mehr. Fragen Sie uns!

News Blog

Rund um die Hebebühne

In unserem Blog halten wir Sie über aktuelle Entwicklungen auf dem Laufenden. Weitere Neuigkeiten finden Sie auf unseren Social-Media-Kanälen.

Finden Sie die Hebebühne, die zu Ihnen passt!

Hebebühnen Service

Laden Sie sich Produktinformationen, Zertifikate und weitere nützliche Unterlagen zu Ihrer neuen Hebebühne herunter!

Hebebühnen kaufen

Sie haben noch Fragen zu Ihrer zukünftigen Hebebühne? Unsere Vertriebs- und Servicepartner helfen Ihnen gerne weiter. Hier finden Sie die richtigen Ansprechpartner für Ihre Region:

Sie benötigen ein individuelles Angebot für ein besonderes Projekt? Durch Konstruktion und Produktion im eigenen Haus können wir auf Ihre Wünsche und Anforderungen maßgeschneidert eingehen. Sprechen Sie uns an! Bei uns sind Sie in wirklich guten Händen!